The world of soldering robot

The definition, how-to-use, applicable soldering methods

Applicable soldering methods

Contact (iron tip), Laser, Ultrasonic

The most of our web visitors might be familiar with this method. Contact soldering is the most matured method with hundreds years. The most of assemblers adapt this basic principle for soldering robot application.

The most important characteristic of laser soldering is its non-contact soldering ability, and there is no contact at all with either the PCB or the component. There is no physical load placed on the PCB, only laser beam and the solder supply. Laser’s great advantages are in its ability to efficiently apply pinpoint heat, to apply beam to confined spaces where a tip cannot fit, and to handle tightly-spaced assemblies, by changing the light angle and taking other steps. Maintenance work can also be reduced.

Soldering conventionally involves bonding solder (tin) with a metallic substrate. Ultrasonic soldering method is an advanced way that enables solder to bond with glass or non-metallic materials. As renewable energy sources are attaining widespread use around the world, electrodes are being affixed to solar voltaic panels. Ultrasonic soldering has been adopted for this application.

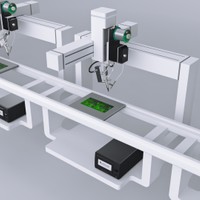

The structure of a soldering robot

A soldering robot is the composite of several core features

Robotic platform

The specification of robotic platform defines its size of soldering PCBs, motion speed and accuracy to reach soldering points. Thus, the quality and accuracy of basic robotic motion is highly required.

The types of soldering head will decide the soldering methods to work. The above three methods would be changed with the appropriate installation of soldering head.

Soldering robots usually use cored solder wire. This feeder delivers the accurate amount of solder for each soldering point. Some feeders can make nicks to applied solder wire in order to reduce solder splatter and balls.

A soldering controller manages temperature of iron tips, the amount & speed of solder feed and synchronization with robotic platform. This is the core and brain of soldering robot to effect soldering quality and outcomes.

Copyright (C) 2017 SOLDERINGROBOT.COM